Introduction

Marine and chemical businesses encounter some of the harshest conditions on the planet—consider relentless saltwater, nipping acids, and slurry abrasives that chew up equipment like it's candy. Pumps are the workhorses of these operations, conveying fluids through systems that cannot afford to fail. At the core of these pumps are pump castings, carefully engineered parts that are built to resist corrosion, pressure, and wear. This article explores the materials, manufacturing processes, design requirements, and maintenance practices behind corrosion-resistant castings for pumps that are the workhorses of these sectors. It's full of realistic, hard-fought tips for engineers, manufacturers, and leaders who want to keep their systems humming in the most extreme conditions.

Materials That Can Take a Beating and Keep Coming Back

The proper material for castings for pumps is not a decision—it's a lifesaver. Marine and chemical environments require parts that can withstand corrosion, mechanical forces, and work under very severe conditions without any performance loss.

Stainless Steel: The Heavy-Duty Standard

Stainless steel, especially grades such as 316 and duplex alloys, is the workhorse of corrosion-resistant pump castings. The key is in the chromium—15% or higher, which creates a protective oxide coating to repel saltwater or acid fluid attack. Grade 316, with a little bit of 2-3% molybdenum, is extremely resistant to pitting corrosion in environments with high chloride concentration, such as seawater. Duplex stainless steels, combining both austenitic and ferritic structures, offer additional strength and thus make them more suitable for high-pressure chemical pumps that are designed for volatile liquids.

Nickel Alloys: Designed for the Worst

Nickel-based alloys such as Hastelloy and Monel are materials that are able to deal with the most challenging scenarios, including sulfuric or hydrochloric acid. Such materials do not just keep going; they even increase in energy when under such conditions that would be fatal for other metals. Monel, for example, dismisses seawater corrosion with a shrug, which is why it's so popular with marine pump impellers. Sure, they're expensive, but when one failure might shut down production or trigger a safety emergency, the expense is worth it.

High-Silicon Cast Iron: Strong on a Dime

High-silicon cast iron, with 12-15% silicon loading, keeps pace with oxidizing acids such as nitric and sulfuric. It's a budget-friendly choice for chemical pumps handling abrasive slurries. The catch? It's prone to brittleness, so designers have to plan for vibration or impact so cracks don't become a disaster.

Non-Metallics: The New Innovations

Fluoroplastics such as PTFE and PVDF, and ceramics such as silicon carbide, are changing the game for chemical plant pump castings. Fluoroplastics have a broad capability to handle corrosive fluids ranging from hydrochloric acid to alkalis, and tend to appear as linings or casings. Ceramics with their hard-as-rock surfaces are ideal for seal faces and bearings in abrasive environments. But even they're not immortal—lower mechanical strength makes them less than ideal where high-pressure systems must be employed.

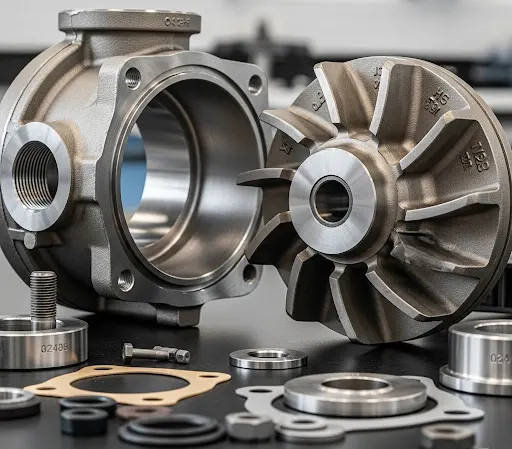

Making Castings That Don't Fail

The alchemy of castings for pumps occurs in manufacturing. Accurate techniques transform raw materials into parts that can withstand a beating and continue to perform.

Investment Casting: Accuracy in Every Curve

Investment casting, an art that has been mastered by Super Quali Cast(India) Pvt. Ltd is the preferred process for intricate pump components such as impellers and casings. It begins with a wax pattern, covered by a ceramic shell, and then injected with molten metal. What is produced is a part with close tolerances and polished surfaces that are resistant to crevice corrosion. The process excels with stainless steel and nickel alloys, yielding parts with uniform strength and low defects.

Sand Casting: Large Pieces, Low Price Tag

For big pump casings, sand casting gets the job done without costing an arm and a leg. It's the way to go for cast iron or aluminum alloys. New sand casting has upped the ante, with enhanced molds giving finer finishes and precision. In marine environments, anodized or coated aluminum sand castings offer light, corrosion-resistant solutions.

Finishing Touches That Increase Endurance

Post-casting operations such as heat treatment and surfacing finishing bring the level up a notch. Annealing seizes stainless steel's structure, and passivation removes surface impurities to fortify the oxide layer. For pumps operating against abrasive slurries, surface coatings such as cobalt-chromium-tungsten alloys provide an armoring layer against wear and corrosion.

Cracking the Code on Corrosion

Corrosion that is caused by a marine and chemical environment is represented by a number of different types, each of which has a different method of attacking pump castings. Understanding these threats is crucial for a successful selection of materials and durable system design.

Pitting and Crevice Corrosion: Silent Saboteurs

Pitting corrosion appears as small, erosive holes, particularly in chloride-heavy environments such as seawater. Crevice corrosion hits in confined areas—consider flange fittings, where suspended fluids devour the metal. Stainless steel 316, which is an alloy with extra molybdenum, resists corrosion because the oxide layer is very stable.

Microbial Corrosion: Nature's Sneaky Assault

In the marine context, microorganisms from untreated water produce biofilms that initiate corrosion through dirty byproducts such as sulfuric acid. High-silicon cast iron and coatings curtail the development of biofilms, thereby controlling microbial corrosion.

Erosion-Corrosion: A Cruel Tag Team

Abrasive particles remove protective oxide layers on the surface of metal, which results in erosion-corrosion. Thus, the metal becomes unprotected and can be attacked by chemicals. This is quite a big issue in pumps that are used for transporting fluids or slurries at very high speeds. Nickel alloys and ceramic coatings emerge victorious, standing their ground against this twin hazard.

Designing Pumps That Stay in the Fight

Smart pump design pairs materials with engineering know-how to maximize durability and efficiency. Here’s what makes castings for pumps perform like champions.

Keeping Fluid Flow Smooth

Impellers and casing must maintain fluids in motion without turbulence or cavitation, which accelerates corrosion and wear. Precision casting provides smooth internal surfaces that minimize flow resistance and erosive local attack. Computational fluid dynamics (CFD) analysis simulates impeller shapes for maximum flow, minimizing stress, and maximizing performance.

Seals That Don't Back Down

Gaskets and mechanical seals are the guardians, keeping leaks from bringing corrosive fluids into contact with castings. Fluoroplastic seals, such as PTFE, resist chemical attacks but must be properly maintained—sufficient coolant flow prevents overheating. Seal face wear checks must be made a regular practice in abrasive conditions.

Playing by the Rules

Castings for pumps should comply with severe specifications such as ASTM A351 for stainless steel or NACE MR0175 for sour service conditions. These standards guarantee that materials can withstand given conditions. Castings in duplex stainless steel certified to ASTM A890, for instance, are established as resistant against stress corrosion cracking in chemical plants.

Real-World Victories

Nothing demonstrates the value of corrosion-resistant castings for pumps more than anecdotes from the field. These testimonials illustrate how intelligent decisions fix genuine issues.

Offshore Oil Platform: Duplex Stainless Steel Saves the Day

One of the North Sea oil platforms suffered pump failures due to corrosion by seawater. Duplex stainless steel impellers and casings, manufactured via investment casting, reduced maintenance requirements by 40%. The high strength of the alloy enabled thinner, more efficient parts without compromising toughness.

Chemical Plant: Fluoroplastic Linings Win Big

One sulfuric acid processing plant fought ongoing corrosion in cast iron pumps. Fluoroplastic-lined castings for pumps froze out leaks and added three years to service life. Coupling these linings with high-silicon cast iron casings was a wise compromise between affordability and longevity.

Innovations That Change the Game

The world of corrosion-resistant pump castings is moving fast with new materials and processes pushing performance and sustainability to new levels.

Additive Manufacturing: Custom Castings, Less Waste

Additive manufacturing (3D printing) allows manufacturers to create custom alloy castings to specific requirements. Titanium-based pump castings, built layer by layer, offer unmatched corrosion resistance for extreme marine environments. This also reduces material waste, a win for the planet.

Green Coatings for a Better Tomorrow

Plant-based coatings such as those by Esgard offer environmentally friendly corrosion protection. With no petroleum solvents, they resist acids and hydrocarbons and have a high flashpoint (450°F) for safety in explosive chemical environments.

Smart Materials That Think Ahead

Embedded sensors in pumps are a revolutionary, smart material that detects corrosion in real time through pH or conductivity changes. The systems provide early warnings and make sure that failure never happens in out-of-the-way marine applications where maintenance is a logistical nightmare.

Maintenance That Keeps Pumps Humming

Maintenance may not be glitzy, but it's the ticket to keeping corrosion-resistant castings for pumps running at their best.

Inspections and Cleaning Done Smart

Periodic inspections detect pitting or crevice corrosion before they get beyond control. Pump internals cleaning with non-abrasive agents prevents biofilm growth, particularly in saltwater systems. Chemical pumps flushing with compatible fluids remove corrosive deposits.

Lubricate and Seal Savvy

Proper lubrication for bearings and seals prevents overheating, which can accelerate corrosion. Check coolant and flush lines before startup to keep seals in top shape. Limit seal leakage to a few drops per minute to lubricate without wasting fluid.

Data Driven Maintenance

IoT sensors in pumps track vibration, temperature, and corrosion rates. Data analytics tells you when castings are at risk so you can repair them before they fail. This is a lifesaver in chemical plants with dozens of pumps running 24/7.

Economic and Environmental Wins

High-quality castings for pumps come with a higher price tag, but they pay off in spades. Duplex stainless steel or fluoroplastic-lined castings are more expensive to purchase, but their longevity cuts replacement and maintenance costs. One chemical plant utilizing nickel alloy castings reduced maintenance costs by 30% in five years. Environmentally, the castings avoid leaks of dangerous chemicals, preserving ecosystems. Sustainable manufacturing, such as that at Super Quali Cast (India) Pvt. Ltd, also reduces waste and energy consumption.

What’s Next: Trends and Challenges

The future of corrosion-resistant castings for pumps is vibrant with new opportunities, but not without some challenges. Superalloys are costly, and precision casting requires highly skilled workers. Increasing the scale of additive manufacturing and coming up with cheaper coatings for hard-to-treat conditions are the most important things on the list. Exploration and cooperation driving the development of hybrid alloys—where the properties of stainless steel and titanium are combined—may give new meaning to pump design. Stricter environmental laws will also be the main driver for greener materials and methods.

The Bottom Line

Corrosion-resistant castings for pumps are still a known elements that support the marine and chemical industries. Employing materials of advanced character, such as stainless steel, nickel alloys, and fluoroplastics with precision manufacturing and smart design, these castings enable the tackling of the harshest conditions. Practices based on regular maintenance and innovative techniques give them a new lease of life. As industries become more demanding for efficiency and sustainability, castings for pumps will still be the elemental support of safe, reliable fluid management all over the globe.