Emerging tomorrow’s Manufacturing Leaders

SQC Investment Castings is a pioneering global exporter and manufacturer specializing in premium Machined investment castings. We want to provide our consumers with the greatest degree of efficiency and, to their supply chain, the most value. Our strategic alliances with many engineering industry giants attest to the achievement of our goal of a business wishing to be the chosen supplier for our clients.

Compared to many other methods, investment casting provides the designer with infinite possibilities and liberties. Working with our customers using a hands-on method enables them to always find this possibility in fresh uses for our precision castings in today's lean, cost-aware production environment.

We are adaptable to our clients' demands and provide a degree of service on which we are happy to claim our long-term partnerships are founded. From idea to execution, we collaborate with our customers; we can even provide complete final machined parts, tested, certified, and ready for use.

What are Machined Investment Castings?

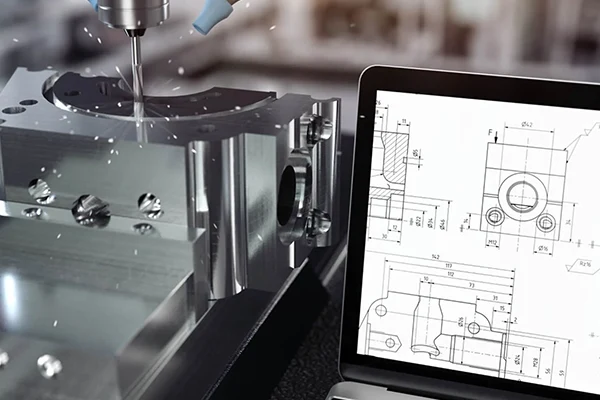

Machined Investment casting is also known as lost-wax casting. Today, many engineers need machined investment castings because of the exact dimensional criteria, strict tolerances, custom profiles, drilled holes, etc, that they offer. Even if "net-shape" or "near-net-shape" cast components significantly save secondary processing expenses, others do. Investment casting engineers may cut or eliminate machining up till now needed on sand castings, fabrications, or forgeries throughout the design-for-manufacture phase. However, the machining needs of investment castings will be lower than those of sand castings or welded fabrications.

The Investment Casting Process At SQC

Investment casting at SQC is a step-by-step procedure that includes multiple key steps. Every procedure supports the quality of the end result. From aircraft to military equipment, our excellent procedure produces premium metal components for several sectors. The process is as follows:

- Injection molding produces wax patterns.

- Pattern assembly into clusters.

- Constructing ceramic shells by successive dipping.

- Melting the wax to produce empty molds.

- Pouring precisely prepared molten steel.

- Solidification and cooling.

- Elimination of ceramic shell.

- Finishing techniques include quality testing, heat treatment, and cutting.

Our Capabilities

Our industry has evolved as a result of our dedication to innovation, which has enabled us to provide cutting-edge services such as fast prototyping, solidification modeling, and 3D design support for castings and associated tools for our customers.

Advanced Facilities

Equipped with modern CNC machining centers and tooling systems.

Material Versatility

Knowledge in working with superalloys, alloy steel, carbon steel, and stainless steel.

Custom Solutions

From prototypes to mass manufacturing, we provide custom solutions with close tolerances and consistent quality.

Robotic Precision

Advanced robotic systems guarantee perfect finishes by improving our coating procedures.

Our Certifications

"SQC is proud to hold industry-recognized certifications, guaranteeing that our products meet the uppermost standards of quality, security, and steadfastness."

Choices of materials

Our business uses several different metals. From stainless steel to brass, we can cast the appropriate material for your project. We're adaptable as well; if you require a particular metal combination satisfying EN, GOST, JIS, Or IS, We Can Make That Happen.

Among our materials are several varieties of stainless steel, low-alloy steel, and carbon steel. Everyone has various uses and benefits. We also deal with unique metals including nickel-based alloys. From robust, rust-resistant materials to those with particular strength, we have choices to suit your requirements.

Industry served

Uses

Trusted in many sectors, our machined investment castings include:

Aerospace

High-performance parts for vital uses.

Automotive

Exact components for improved safety and efficiency.

Industrial Machinery

Strong parts for heavy-duty use.

Medical Devices

Dependable components for life-saving devices.

Contact Us

We would be happy to discuss, do an online conference, or even come see you to go over your casting solution needs. We invite you to check our facility to see some of the cast goods we can manufacture, or just get in contact to know more about our products.