Introduction

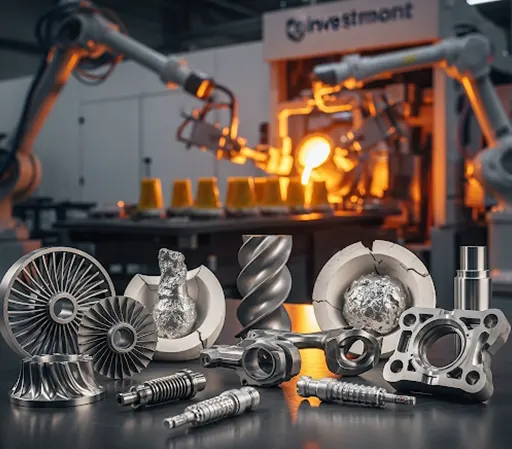

Sophisticated component design is no longer a nicety in contemporary manufacturing—it's a requirement. Aerospace and biomedical industries call for parts that are geometrically complex, lightweight, and high-performance. Investment casting has taken its rightful place in the industry due to its singular capability of producing near-net shape parts of exceptional detail. The question is—how do investment casting manufacturers produce such complexity, accuracy, and structural integrity on a regular basis?

Let's unwind the whole process and the accompanying technological advancements that make it possible for manufacturers to achieve such stringent requirements.

Accuracy from the Beginning: Advanced Wax Patterning Role

Investment casting starts with the shape of the end product as wax. But it is not ordinary wax—it is an engineered material designed to provide sharp edges, close tolerances, and dimensional stability.

Patterns applied today are created through high-pressure injection molds precise to hundredths of a millimeter. Precision-machined metal dies are used to create these molds, which enable investment casting manufacturers to reproduce intricate geometries multiple times with absolutely no deviation.

In addition, wax materials are reinforced by additives that enhance flow behavior. This provides for complete filling of each corner, internal cavity, or thin wall. The use of collapsible wax cores has made the production of hollow structures and internal channels—something thought impossible before- commonplace today.

Building the Shell: Ceramic Coatings That Define Surface Detail

Once the wax pattern is made, it's slathered with a proprietary ceramic slurry. This isn't a protective coating—it's a mold containing every contour and micro-detail of the original pattern.

The ceramic employed here is not commodity-based. High-purity silica or zircon-based slurries are custom-formulated for specific alloy types and casting temperatures. The grain structure is designed to capture and hold the sharpest features possible, even fine print or threads.

Layer upon layer, the shell is constructed, usually 7 to 9 coats. Each coat is dried in controlled humidity and temperature conditions to facilitate even development of strength. The outcome is a mold that is resistant to severe thermal shock and contains intricate 3D geometries with accuracy.

To add additional complexity, contemporary investment casting manufacturers use methods such as freeze-gel casting and sol-gel processes. These permit quicker shell building and tighter control of surface finish and shrinkage rate.

Melting the Wax, Maintaining the Shape

The second stage—dewaxing—is perhaps the most important. If executed improperly, the entire ceramic mold might crack or become distorted, particularly in the case of thin walls or sharp radii.

Autoclave dewaxing is common, where high-pressure steam melts and flushes out the wax rapidly without straining the mold. Flash-fire methods are employed by other manufacturers, burning the wax off immediately and without residue. All these techniques maintain the integrity of the shell so that the geometry is not disturbed.

It's here that decades of experience come into play. The top investment casting manufacturers schedule every step with precision. Preheating and burnout of the wax are carried out on a mathematically derived temperature curve, assuring dimensional control.

Pouring with Precision: Alloy Selection and Fluid Dynamics

The metal pouring operation is where metallurgy meets geometry. The alloy must be clean, homogeneous, and at the optimal pouring temperature. Otherwise, deviation will cause shrinkage, porosity, or distortion.

Vacuum melting and induction melting are applied for delicate alloys such as titanium or Inconel. For aluminum and steel, inert gas shielding prevents oxidation.

Pouring is not a random act. It's a process that is controlled with consideration to metal fluidity, mold temperature, and even mold orientation. For very complex geometries, bottom-pour methods or counter-gravity pouring are employed. This ensures an even metal fill of the mold without air entrapment and voids.

When internal structures are essential, ceramic cores or salt cores are placed within the mold. Once cast, they are leached out, leaving precise internal cavities that cannot be machined.

Managing Shrinkage: Simulation and Digital Tooling

Perhaps investment casting's largest challenge is forecasting how the metal will shrink as it cools. All alloys contract differently, and geometrically complex parts contract non-uniformly.

This is where simulation fits in. Investment casting manufacturers employ software such as MAGMASOFT or ProCAST to model metal flow, solidification, and shrinkage digitally. The system can detect hotspots, turbulence regions, and sites where porosity might occur, before the casting is produced.

Tooling may then be made up. In case a thin wall is going to contract more, the die in wax is trimmed so that it becomes slightly thicker in that particular section. After hundreds of castings, this provides consistent dimensional outcomes and cuts down scrap rate considerably.

Firms such as Super Quali Cast (India) Pvt. Ltd. spend heavily on simulation-based tooling design. This enables them to supply sensitive industries such as defense, oil & gas, and medical with components having zero-defect tolerance.

Post-Casting Enhancements: From Complex to Functional

After the casting has been taken out of the shell, the process has not finished. The removal of the casting from the shell is just the beginning of the journey with complex geometries. Heat treatment is a typical way of improving the mechanical properties of a metal, such as hardness, ductility, or corrosion resistance, depending on the use it is being done for.

Testing methods that do not cause damage to the part, like ultrasonic testing, X-ray, or dye penetrant inspection, facilitate local and internal integrity information. It is a very important factor when it comes to aerospace and surgical parts.

The machinists use around precious spots—such as the perfect places for sealing or attaching holes—CNC machining for extremely complex parts. However, the volume of the machined part is nevertheless minimal since the casting is already nearly the final shape.

Also, investment casting manufacturers may carry out some surface finishing processes such as shot blasting, polishing, or even electropolishing. It is good for both appearance and performance, especially in the flow-sensitive parts like turbine blades or fuel injectors.

Lean Manufacturing and Mass Customization

Contemporary industries require two conflicting items simultaneously: mass production and customization. Investment casting alone meets both requirements.

Although tooling cost is comparably low and setup time is quick, short runs are cost-effective. However, with modular tooling, foundries can provide custom variations without re-establishing the whole mold. For example, a base impeller casting can have various shaft bores or vane angles tailored to each customer, without new dies.

Investment casting manufacturers are additionally bridging the gap with lean manufacturing principles such as just-in-time inventory, electronic order monitoring, and waste reduction. This achieves a quicker response and uniform quality.

Material Pairing Strategies for Complex Castings

Even if the casting design is complicated, the good result is still dependent on the proper choice of a material that is not only durable but also has a good interaction with the mold and the filling system. The materials necessary for the casting process by investment casting manufacturers have to be more than just heat-resistant. They should be able to flow, solidify, and release with accuracy along with the heating process. In addition, if it is necessary to use several alloys in one part of the component, the situation becomes even more difficult.

Here's a comparative look at how some commonly used alloys behave in complex geometries:

Using the wrong alloy in a part with micro-channels or tight ribs could result in incomplete fills or stress points. That’s why pairing the alloy to the geometry is a science in itself. Top investment casting manufacturers often conduct trial pours and simulate flow using CAD-CAM analysis to get it just right.

Tooling and Mold Innovation in Achieving Geometric Fidelity

Ask any foundry veteran, and they’ll tell you—you can’t achieve complex geometry without mastering the mold. That’s why tooling has become a field of innovation all on its own. Today, some of the most forward-thinking investment casting manufacturers are combining traditional tooling with 3D printing, silicone-backed rubber molds, and even modular dies to bring down costs while elevating precision.

Take, for instance, turbine blades with internal cooling passages. These are traditionally impossible to cast with sand cores or even ceramic cores. But with the advent of soluble wax cores, manufacturers can produce negative space inside a part as thin as a millimeter—something that would have been unimaginable a decade ago.

In addition, when it comes to modular tooling, a master mold can be changed for a variety of parts. Speeding up the production process and also lessening tool fatigue, which means that the accuracy of later batches won’t decrease over time. That’s a great time when you are making tens of thousands of identical, intricate parts for industries like defense or automotive.

In some high-volume facilities, real-time sensor feedback is used to adjust temperature and pressure during the pour, essentially allowing the mold itself to "talk back" to the pouring machine. It’s no longer just about the mold shape. It’s about making the mold intelligent.

The Impossible Achieved: Case Examples of Geometric Excellence

Investment casting over the past ten years has created parts once thought to be unmanufacturable. Some examples are:

- Hollow-bladed impellers with internally routed cooling channels for use in jet engines.

- Knee implants with porous lattice geometry replicating human bone for osseointegration.

- One-piece fuel injector blocks for diesel engines with five or more internal passages.

These parts are no longer on paper—today, precision-guided investment casting manufacturers make them a reality. Methods like the use of 3D printed wax models for rapid prototyping have increased what's geometrically possible.

Future-Driven Techniques: Where Complexity Is Going

The future of complex casting is through digital hybridization. The foundries are combining additive manufacturing with conventional casting to expand the limits.

For instance, 3D printing is being utilized to make ceramic cores with labyrinthine inner geometries. These are placed in wax assemblies and cast normally.

Machine learning is also in the research stage to streamline mold drying, dewaxing, and alloy temperature control, eliminating guesswork in these operations.

Sustainability is also on the radar. Reusable mold material, reduced energy melting methods, and improved wax reclamation systems are being engineered by market leaders such as Super Quali Cast (India) Pvt. Ltd.

Conclusion: Complexity Is Now the Norm

Something that was once a weakness is now a differentiator. Complex geometries are no longer the preserve of niche industries—they're the norm across industries. And investment casting is at the center of this revolution.

With improvements in wax tooling, ceramic material, computer simulation, and controlled metallurgy, modern-day investment casting manufacturers now commonly produce elaborate, functional, and high-performance components equal to precision machining, often at a very low fraction of the expense.

Their accomplishment is not through chance, but through discipline, engineering insight, and obsessive optimization. As the world's industries increasingly require even greater complexity, the casting industry has made one fact unmistakably clear: complexity is no longer a problem—it's the new standard.