For a critical field like the choice of material for industrial needs, the decisions made in regard to cast steel vs carbon steel play a critical role. Such a head-to-head scenario in relation to the two very often is performed for both widely utilized materials when it comes to manufacturing processes and having advantages over particular domains. A profound knowledge of these differences in performance, operational requirements, cost, and functional capabilities enables designers, engineers, and other manufacturing personnel with respect to various specific end uses.

Although there is some overlap in the characteristics of carbon steel and cast steel-most notably, the composition as alloys primarily of iron and carbon-the two materials are quite different regarding characteristics, methods of processing, and ultimate use. The following article will look into the various important differences between these two materials, analyze why lowbrow often triumphs in casting when it comes to carbon steel, and explore their applications. In so doing, we will show why the choice of cast steel vs carbon steel often depends on cost-effectiveness, ease of fabrication, and/or mechanical performance requirements.

What is Carbon Steel?

Carbon steel is basically an alloy containing iron and carbon, with the inclusion of other elements in trace amounts like manganese, silicon, and copper. The carbon content in carbon steel may range from a minimum to a high content and hence is versatile to adapt to different requirements. This alloy is classified based on the amount of carbon it contains, with three main categories:

- Low-carbon steel (mild steel): Contains less than 0.3% carbon. This class of low carbon steel, due to its fairly low composition of carbon, is also quite able to weld, twist, and form into different shapes. Hence, their application has been found in general purposes where high strength or hardness is not required.

- Medium-carbon steel: Contains between 0.3% and 0.6% carbon. This type of steel is balanced for applications requiring moderate strength since its strength, ductility, and hardness act in concert.

- High-carbon steel: Their carbon percentage falls between 0.6% and 1.0%. It is well known for superior hardness and strengths, yet less ductile compared to steels with low composition because its greater carbon content makes the metal more brittle.

Carbon steel castings is probably one of the most versatile materials used in manufacturing today. Everything from parts for automotive to structural can be manufactured with carbon steel. Its ease of fabrication, combined with relatively low material costs, makes it the material of choice for a host of applications.

What is Cast Steel?

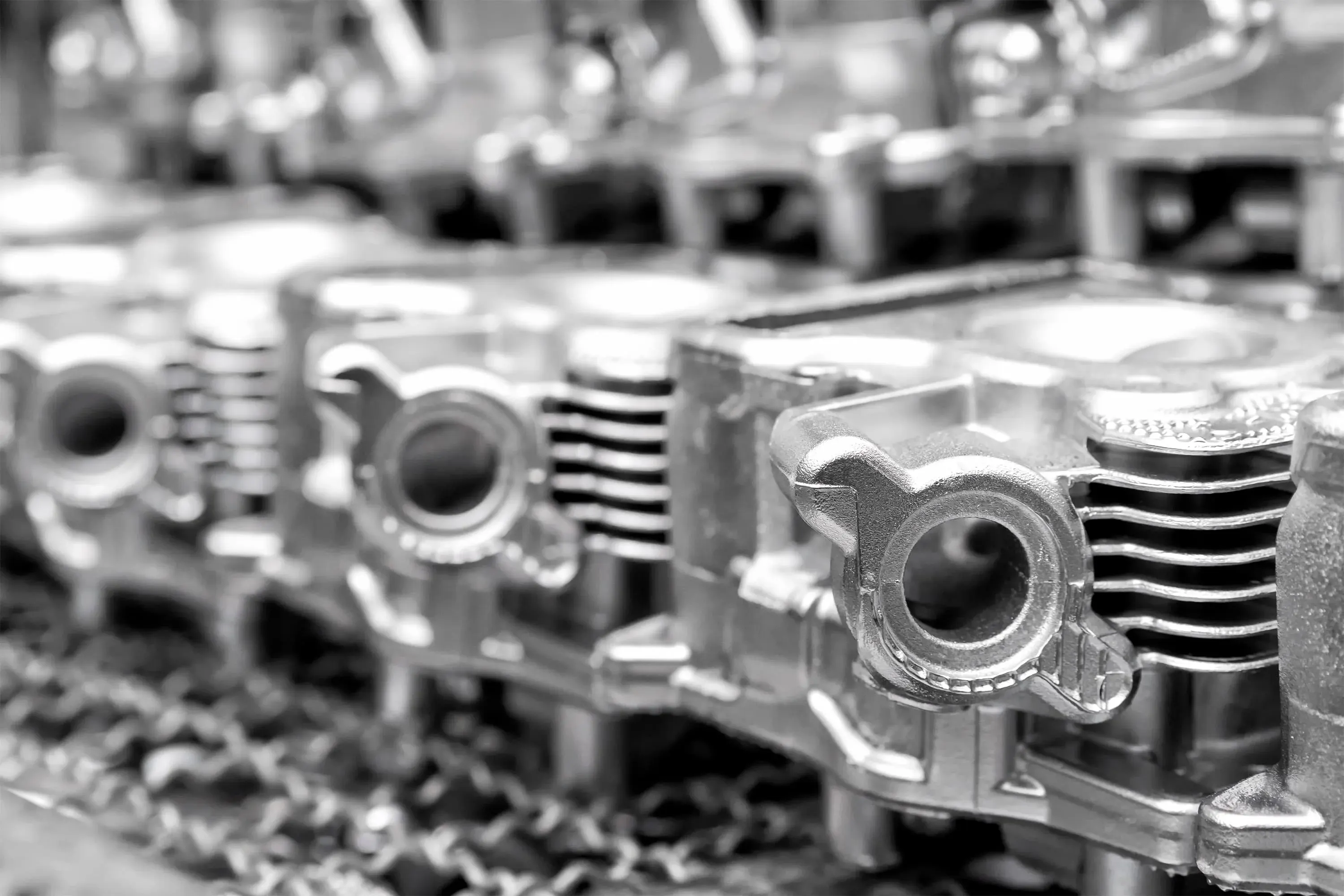

Unlike carbon steel, cast steel has been designed especially for the casting process. In the casting process, molten steel is allowed to flow into molds, wherein it solidifies to take the desired shape. Cast steel allows flexibility in terms of its composition, and because of this very reason, the alloy can be used in specialized applications. This type of steel is usually alloyed with such elements as chromium, nickel, molybdenum, and several others, enhancing mechanical properties like wear, hardness, and, ultimately, durability.

The composition of cast steel can vary widely, enabling engineers to adapt the properties of the material to the demands of particular applications. Some cast steels are intended to be resistant to corrosion, while others are designed for strength at high temperatures or wear resistance. Cast steel is used in various complex shapes, and thus is an important factor for high-performance sectors like heavy machinery, automotive engines, and major construction projects.

Cast Steel vs Carbon Steel: Key Differences

At face value, cast steel vs carbon steel can almost be considered as virtually the same material, since these happen to be derivations of iron alloy. Yet, their differences are deep and affecting uses to which either is put to. Let us look deeper at these differences.

1. Manufacturing Process: Shaping and Forming

The most apparent difference in the cast steel vs carbon steel is derived from their very process of manufacture. Carbon steel is generally produced through a simple process involving the melting of iron, adding carbon to it, and then rolling or forging the product into sheets, rods, and plates. This process is quite uncomplicated and thus can easily be scaled for mass production.

In contrast, cast steel is a product from the melting of steel that, while cooling and solidifying in moulds, gives a preselected shape. The casting process is actually the particular advantage of cast steel-its complex geometries. Cast steel would be perfect for those parts requiring intricate shapes, such as curved or hollow parts that cannot easily be realized with the conventional rolling or forging techniques. The capability of making special molds also means that cast steel can be created to make components with more complicated designs than carbon steel.

2. Material Composition: Alloying Elements' Role

One of the important differences between cast steel vs carbon steel is their material composition. Carbon steel mainly consists of iron and carbon with minute traces of additional elements such as manganese, copper, and silicon. The simplicity of this composition makes it easy and cheap to produce; on the other hand, carbon steel properties can be changed according to the carbon content.

On the other hand, cast steel often contains a high amount of certain other elements. Some of the generally used alloying elements in cast steels are given below:

- Chromium: Enhances hardness, wear resistance, and corrosion resistance.

- Nickel: It increases toughness and resistance to impacts.

- Molybdenum: It strengthens at high temperature, thus improving wear resistance.

- Vanadium: It hardens the material and increases its strength.

These alloying elements make cast steel more robust in certain conditions. With the higher alloy content, cast steel is resistant to wear and corrosion, and to high-impact stresses, hence found suitable for applications requiring durability and performance.

3. Mechanical Properties: Strength, Toughness, and Hardness

On comparing the mechanical properties between the cast steel vs carbon steel, the differences that arise are just outstanding:

- Carbon Steel: The properties, such as strength and hardness in carbon steel, are directly connected with the element composition of carbon it contains. When the carbon percentage in the material is low, this type of carbon steel can easily be shaped and welded or even fabricated but would not have more strength as its higher variants would. Increasingly, carbon is added to the steel and increases its hardness, making the material more brittle with less ductile characteristics. Generally speaking, carbon steel is less tough compared to cast steel; thus, it is not ideal for those applications that require high resistance to impact or sudden stress.

- Cast Steel: The different alloying elements that are included in cast steel considerably improve its strength, toughness, and resistance to wear. Cast steel is in general, much stronger and tougher than carbon steel, thus usable in applications where components undergo extreme conditions for top performances. Cast steel can better sustain high-impact forces, high-temperature environments, and abrasive wear. Therefore, cast steel is absolutely suited for heavy machinery and high-stress structural components.

4. Applications: Where Each Material Excels

The difference in properties and performance causes such differences in the uses of cast steel vs carbon steel across industries.

- Carbon Steel: Various construction materials are manufactured from carbon steel, being versatile. Further, the relative inexpensiveness and ease of fabrication make them a first choice where high strength is not explicitly required, such as structural beams and pipes, parts for automobiles, and general machinery components. Carbon steel investment castings are perfectly suitable for situations that require merely simple design and economization.

- Cast Steel: On the contrary, cast steel is used when much higher strength and toughness, apart from geometrically complicated shapes, are required. Cast steel applications comprise heavy machinery, automotive engine parts, industrial machinery, and bridge as well as crane structures. In relation to this, the casting process can provide details in a part which cannot be easily done by other methods at their disposal. It is a material of choice when the parts are subjected to extreme forces, temperatures, and wear.

5. Cost Considerations

One of the most key reasons why a lot of manufacturers will always use carbon steel over cast steel has to do with cost. In general, carbon steel tends to be cheaper because the production process is quite a bit easier. It is simple to produce large volumes of carbon steel using rolling and forging processes. Carbon steel's composition is not as intricate; therefore, this too drives down its costs of production.

In contrast, the more notorious reputation of cast steel can be pricey to make since it requires special casting equipment and molds, with more complex material formulations. Besides, a lot of time and much labour is involved in the casting processes to guarantee the quality and integrity of the finished part. As a result, cast steel is reserved for high-performance applications whereby benefits from superior mechanical properties justify the increase in cost.

6. Simplicity vs. Complexity in Design

One important differentiation between cast steel and carbon steel is in design considerations. The choice of design for carbon steel will typically be used in less complex designs where cost, ease of manufacturing, and rapid production are required. Since the material can easily be welded, forged, and machined, it is commonly used for run-of-the-mill purposes. In these, the simplicity of the design is all that is required, and carbon steel provides a sturdy, economically viable solution.

Cast steel, however, finds its real place when complicated and intricate shapes are involved. The possibility to make special molds and cast pieces with specific geometries using casting provides much more room for design freedom. So, the use of cast steel is really to make high-performance parts with challenging designs, such as engine blocks, gears, and turbine blades. While the manufacturing process is more involved, the capability to make extremely specialized parts makes cast steel a very valuable material in highly advanced engineering projects.

Why Simplicity Wins in Casting: The Case for Carbon Steel

While both cast steel vs carbon steel have their merits, the principle of simplicity often gives carbon steel an upper hand in many casting applications. Here's why simplicity wins:

1. Reduction of Production Costs

As mentioned earlier, carbon steel is less expensive to produce than cast steel. The plainness of the composition, combined with more straightforward processes, is conducive to economies of scale and thus a better price for high volume. In most applications, carbon steel's performance characteristics are quite satisfactory, thus it's often a first choice due to cost considerations.

2. Better Turnaround Time

As carbon steel is easily forged, welded, and machined, production is quite often faster than it is with cast steel. The reason for such a case includes the fact that the casting process with cast steel sometimes can be very long since some parts boast large or generally complicated geometries that force the use or making of special molds. In such an industry where speed of production is crucial, carbon steel does hold a greater advantage in relation to lead times.

3. Design and Fabrication Simplicity

For many applications, simplicity in design and fabrication using carbon steel is sufficient to meet the required performance standards. Beams, structural supports, and pipes can easily be fabricated from carbon steel using common manufacturing methods. This eliminates the need for the more complex and expensive casting process, thus enabling faster and more cost-effective production.

Conclusion

The question of cast steel vs carbon steel depends, in large measure, on the particular needs of the application. While offering superior strength, toughness, and wear resistance, the benefits of cast steel are many; however, carbon steel will often be the better choice when the factors of cost, ease of fabrication, and simplicity in design are dominant.

In the end, simplicity wins when the application does not call for the high-performance characteristics that cast steel offers. With its lower production costs, faster lead times, and ease of fabrication, carbon steel is often the go-to material for many industrial applications. But for those specialized parts that require very strong, durable, and complexly shaped parts, cast steel remains an indispensable material in engineering.