The military world is changing, and as fast as new technologies come to the fore, so do their manufacturing processes need to keep abreast of changes in modern warfare, security, and defence. In such a high demand sector, one of the distinguished techniques that stands out from the rest is defence investment casting, producing high-performance parts in a degree of precision unsurpassed anywhere. Sometimes referred to as the "lost-wax" technique, this process has proved invaluable in the construction of a wide range of defence systems, from aircraft and artillery to naval vessels and electronic systems.

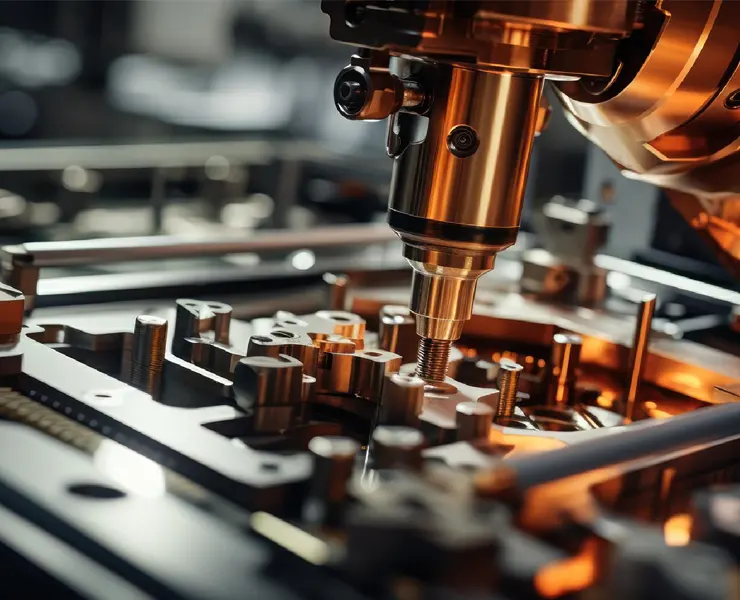

Investment casting makes for very accurate production of parts in metals, allowing the manufacturer to reach pieces that are very detailed and accurate, pieces which meet the tight specifications required in defence applications. Further, it offers quite a few advantages over traditional manufacturing methods, such as the possibility of creating intricate shapes and components without heavy machining. This makes it perfect for industries that ask for reliability, durability, and precision-no more so than in the defence industry.

In this article, we will examine the methods used during the process of defence investment casting, its role in the already cutting and thrust in the modern defence system, and its critical role in the furtherance of military technologies. Investment casting will also be looked at from the perspective of the fast-changing global defence architecture, particularly as the government of India launches its new initiative geared to provide the country greater self-reliance for producing defence goods under "Make in India."

What is Defence Investment Casting?

Defence investment casting is that manufacturing process wherein components are created for the defence industry through a precision technique: creating a wax model of the desired part, coating it in a ceramic shell, and then heating it to melt away the wax, leaving behind a cavity into which molten metal is poured. On cooling, the metal solidifies, and the resulting cast provides a near-net shape with minimal secondary processing. This process allows complex parts to be manufactured with small tolerances and a great deal of structural integrity, which is needed for today's military applications.

Investment casting offers quite a few advantages in that it can make parts geometries that are rather difficult or even impossible to be performed using conventional machining techniques. The method also allows high material utilization, minimizes waste, and produces parts that have excellent surface finishes and need little refinement.

The Role of Precision in Defence Systems

Precision in defence systems is a must, not a luxury. Even the tiniest deviation from perfection can cause any system to fail, go less effective, or-catastrophically worse-in extreme cases. Modern military systems are designed to work amidst extreme conditions, including strong heat and pressure, as well as high mechanical stress. Of course, this is because such systems need all possible perfection in their component-making process.

This is where defence investment casting comes into play, which allows the manufacturing of parts with the most incredible accuracy, each one of which would fit perfectly within a large system. The possibility of repeating complex geometries with the least deviation makes all the difference in the defence application relying much on safety, performance, and reliability.

This also allows the making of special geometrical shapes with extreme precision required for investment castings that can be applied to the making of turbine blades in jet engines within the aerospace sector. Such blades bear much heat produced inside the motor; moreover, they have to be designed so that fuel and air could mix without turbulence. Precision provided by investment casting means all such blades would be correct in shape, thickness, and even surface finish so that all will work well inside an engine.

Likewise, in armament systems, the investment casting process is followed for making parts that come into play under extreme conditions of mechanical stress. From the firing pin of the rifle to the barrel of a cannon, these parts have to be manufactured to exacting specifications so that the particular weapon performs as expected with each use.

Key Applications of Defence Investment Casting

Investment castings for defence has a significant role in many vital industries in the defence field. The main, most crucial products of defence investment casting include:

1. Aerospace and Aircraft Components

One of the most significant areas where investment casting is involved in the defense sector is the manufacture of aerospace components. Aircraft parts, particularly for military fighter jets and other aircraft, require lightweight yet extremely strong characteristics. Components must display high resilience under extreme conditions, including temperature and pressure steadily within the defined limits.

The primary uses of investment casting include the production of jet engine components; for instance, turbine blades, nozzles, and combustion chambers. Because of the need for these components to withstand high temperatures and mechanical stress, investment casting is often the process of choice. It is the precision and strength of the process that allows these pieces to meet the rigorous requirements of modern military aviation.

Besides the engine components, investment casting is applicable to produce other critical parts such as airframe components, parts of landing gear, and control systems. All these components demand to meet exact specifications to provide for the aircraft's safe working, all being made possible due to precision investment casting.

2. Weapons Systems and Munitions

Contemporary weapon system parts require the use of very strong, reliable, and very accurate components. Be they in a tiny personal arm or a heavy piece of artillery, these various components must be resistant to pressure and stress in tremendous conditions of operation. The manufacturing of many different parts is realized through defence investment casting; firing pins, triggers, barrels, and so many more.

Investment casting allows the making of very complex parts, which are also critical for the functionality of weapon systems. For example, in firearms, precision at the firing mechanism can be vital for the accuracy and reliability of a weapon. This is achievable through investment casting, which can make such parts both accurate and strong enough to ensure that the weapon functions under extreme conditions.

3. Naval Defence Systems

Naval vessels and submarines work in some of the most hostile environments in the world. The saltwater and continuous tension in extreme pressure and temperature call for strength in quality and corrosion-resistant parts. Therefore, defense investment casting is done in all areas of the naval sector, including propellers, shafts, valves, and the manufacturing of pressure vessels.

These parts must be designed to withstand heavy mechanical load while at the same time resisting corrosive sea water. Investment casting is ideal in the manufacture of these parts, which demands very strong and corrosion-resistant specifications so that the naval vessels may cope effectively in hostile environments.

Furthermore, the various weapon systems used in navies, from missile launchers and torpedo tubes to the different control systems, still need their components investment cast so that they can be accurately and durably enough for military purposes.

4. Defence Electronics and Communication Systems

All modern defence systems rely heavily on electronics for communication, navigation, surveillance, and control of destructive weapons. Investment casting has been utilized in the manufacture of parts for use in radar systems, satellite communication gadgets, and other electronic devices that characterize modern war.

In most of these systems, the parts have to be small and complex and sometimes operate under a structure of extreme conditions. The precision attained in investment casting enables such parts-like heat sinks, circuit board housings, connectors, and many others-meeting these demands. It is this casting process that has ensured the manufacture of these parts to the exact dimensions needed for proper integration into the larger systems.

5. Advanced Materials for Defence

Investment casting also allows for the use of special materials which are very key for defense applications. The materials very often need to have special properties such as high heat resistance, corrosion resistance, or magnetic properties. With defense investment casting, manufacturers can cast a tremendous diversity of materials, thereby producing components in compliance with high demanding requirements within the defense industry.

Commonly used in the investment casting for defense application range from titanium, high-performance alloys, and superalloys. These elements are chosen based on their performance in extreme conditions, ensuring they are cast to very tight tolerances with the required performance expected of each component.

Investment Casting in Global Defence Manufacturing

As the need for defence evolves, countries are moving towards high-precision methods of manufacturing, such as investment casting, to keep pace with rapidly changing technologies and the ever-increasing demands on reliability and performance. The global defence industry is expanding at an increasingly rapid pace, focusing on precision and advanced materials to suit modern warfare. This means that defence investment casting plays a very key role in ensuring these components will be to the highest standard.

1. Meeting the Demands of Modern Warfare

The modern defence industry is made to work on an increasing number of complex demands. Countries are now putting much emphasis on the technological development and durability of a defence system, which needs to function in every type of extreme environmental condition. From vast areas of deserts to depths of the ocean, in military missions or submarine operations, modern defence mechanisms are supposed to work with flawless efficiency.

Investment casting will be required to make the components of such complex geometries and exacting tolerances to develop parts that can withstand such varied challenges. This technology has versatility in a range of applications in defence, from small arms through large missile defence systems, to make military equipment as advanced and durable as possible.

As nations modernize their armed forces, they increasingly look toward investment casting for solutions that reduce costs, improve manufacturing efficiency, and maintain performance and reliability in high-stakes defence scenarios. This trend is driving some great advances in casting technologies, further solidifying defence investment casting as a key part of defence manufacturing.

2. Cost-Effectiveness of Investment Casting in Defence

Another critical consideration for defence manufacturers is cost-efficiency. With large-scale programs, such as fighter jets, naval vessels, and missile defence systems, complex supply chains and costs arise. It is important to make sure that components are manufactured with minimal waste and time-consuming steps in order to keep costs low while keeping performance high.

Investment casting in defence is cost-effective because the manufacturers can make the most complicated components in one step, mostly without further machining or finishing. As an example, turbine blades in jet engines that needed extensive machining after being cast can now be manufactured to a high degree of accuracy through investment casting, therefore reducing labor and material wastage without compromising on quality.

Besides, the possibility of making such a process for details with minimal wastes means the ability to have a really more sustainable way of manufacturing. The precision of defence investment casting also means less material is used in production, which is highly important when working with very expensive, high-performance alloys and metals.

Case Studies: Defence Investment Casting Making a Difference in the Real World

Case Study 1: Fighter Jet Turbine Blades

The most critical applications of defence investment casting are probably turbine blades for military aircraft engines. These must be capable not only of withstanding very high temperatures but also of delivering good aerodynamic efficiency. The service loads on turbine blades can involve massive centrifugal stresses together with very high temperatures, so failure could be disastrous.

Due to this investment casting process, the turbine blades now have the required strength and heat resistance that has helped in attaining the required conditions of aerodynamics. These turbine blades are manufactured to high degrees of precision, thus assuring reliability and safety for use by military aircraft engines.

Examples include the turbine blades of fighter jets, such as the F-35 Lightning II, whose sophisticated materials include titanium and nickel-based superalloys. Using defence investment casting, manufacturers are able to make blades with intricate cooling channels, thin airfoil profiles, and precision surface finishes, each adding to the efficiency and performance of the engine.

Case Study 2: Naval Propulsion Systems

Submarines require powerful propulsion systems for deep-sea operations. The systems require propellers, shafts, and valves that are capable of working under immense pressures and corrosion from seawater. Most of these parts are manufactured by defence investment casting, ensuring high performance in underwater operations.

For example, submarine propellers are made from high-strength alloy materials that have corrosion- and stress-resistance properties. Investment casting allows for making these components for proper strength, weight, and corrosion resistance. The precision of the casting process ensures that these parts perfectly matched the larger propulsion system-in these high-stakes applications, failure is minimized.

The benefits of utilizing defence investment casting allow manufacturers to create complex, high-performance components that can meet the highly demanding nature of the naval defense sector. This has brought improved operational efficiency and reduced maintenance costs for a range of navies around the world.

Case Study 3: Missile Guidance Systems

Air-to-air and surface-to-air missiles require many very precise components of their guidance systems, which often have to perform under severe conditions. Such systems include sensitive electronics, actuators, and propulsion components that have to operate in harmony.

The process of defence investment casting will hence involve playing a leading role in the assurance of reliability within missile systems through creating components that are extremely precise and durable. Examples are missile nozzles and houses that can be cast to show intricacy in design for realizing maximum performance with minimal weight.

Further, special missile warhead parts need investment casting, as some units have to sustain severe accelerating forces and temperature effects; the exacting processes used in investment casting can deliver components that do not malfunction during extreme situations.

The Future of Defence Investment Casting

More innovation within the defence industry will only increase the role of defence investment casting. The performance, reliability, and cost of military systems are continuously under scrutiny by manufacturers in order to find ways of improving, and investment casting is well-placed to help reach these goals.

It is likely that the investment casting development will continue to improve with advances in materials science and improvements in casting technology. Examples could be the newest superalloys and composites which will make the building of even stronger, lightweight defence system parts possible, improved capability for casting complex shapes due to the development of better pattern materials enabled by 3D printing or maybe incorporating artificial intelligence into the casting process itself.

In this connection, the latest trend for more automation in manufacturing and Industry 4.0 will act as a main driving force towards developing effective and streamlined casting processes continuously. In concert, the automated system for casting and quality control paves the way for effective data analytics that will give manufacturers faster and cost-effective means for making quality and precision components.

How "Make in India" Shapes the Future of Defence Manufacturing

It was because of the "Make in India" initiative taken by the Government of India that such a radical change came into being in the country's defence industry. The program aimed at lesser dependence on foreign imports of defence and building up a self-sustained domestic manufacturing defence sector in the country. For such a vision, one of the top agendas was developing advanced techniques for manufacturing, including investment casting for defence.

The Indian defence industry is growing and has harnessed investment casting for the fabrication of fittings for the swelling military. In pursuit of its dream to be considered a link in the global supply chain, India is not only investing in state-of-the-art manufacturing facilities but forging alliances with international defence companies. This transformation will have investment casting of critical military components as its fulcrum.

The government's stress on self-reliance is urging the adoption of technological innovations within the modern defence manufacturing segment of the country. Advanced casting technology is being taken up increasingly by firms while producing durable, quality parts that would serve many military purposes. Be it in fabricating jet engines, weapon systems, or even in naval vessels, the concept of investment casting in defence is likely to take center stage while India strives to become one of the leaders in the world in respect of defence manufacturing.

Conclusion

Defence investment casting stands at the very forefront of modern military manufacturing, enabling solutions that feature precision, durability, and reliability to make parts that can meet the most exacting demands of today's defence systems. From aerospace to naval systems, weapons manufacturing to missile defence, this technique has proved itself a critical enabler of high-performance, complex parts in these areas.

In this fast-evolving industry, investment casting will continue to be in the fore while manufacturing the next generation of defence technologies. The future in defence manufacturing, with its casting techniques and automation, is bright with the development of Material Science.

Besides, initiatives such as "Make in India" help to make the Indian defence industry much more self-sufficient, capable of manufacturing parts using even the latest technologies, including defence investment casting. As long as India is aloft in manufacturing, it will play its indispensable role in shaping the modern concept of defence.

Precision in modern defence systems is not just a matter of advanced materials and design; it is also essentially related to the great capabilities of investment casting. The defence industry can make more powerful, lighter, and reliable components by tapping into the potential of this technique, hence assuring military systems of further evolution and success in the complex dynamic world of modern warfare.