In this fast-morphing industry of manufacturing, industries are not letting any opportunity get away to strategize and advance their production with minimal cost impact, growing needs for better performance, and sustainability standards. Among many methods of casting, investment casting services have lived through the tide of time. This age-old technique, as required by the modern manufacturing demand, is subject to tremendous change in absorbing new material demands, advanced design complexities, and higher drives toward efficiency.

The continuously changing technologies and market trends have put investment casting firms at the forefront, compelled to change and adapt. This article reviews the demands of modern manufacturing on investment casting services; specifically, it looks into three of these necessary factors for successful completion: design flexibility, material innovation, and production efficiency.

Design Flexibility and Its Role in Modern Manufacturing

A major motivation of most modern manufacturing involves high demands for complicated geometries and high-performance parts right down to finer scales. While some of the traditional methods of investment casting may indeed have lacked the accuracy or intricate forms that many current industries require, in an almost comparable contrast, investment castings India services have been really accommodating.

1. Development of 3D Modeling and CAD Integration

Computer-aided design and engineering have really revolutionized the mode of designing and producing parts. Traditionally, investment casting services were limited by the molds and patterns involved in the process; today, 3D modeling and simulating software allows manufacturers to conceptualize highly complicated and detailed parts with much less effort.

Software work on the computer now allowed the engineers to create intricate features of parts through CAD tools to be directly transformed into patterns for casting. These can also be analyzed in performance, heat treatment requirements, and flow simulations. The result is not only greater design flexibility but also better functionality and efficiency of the product.

For example, both aerospace and automotive manufacturers frequently need high-performance, lightweight parts with very complicated shapes. These industries now have the capability to produce components that had been previously unaffordable or impossible to create with traditional manufacturing due to 3D printing and additive manufacturing with the use of investment casting services.

2. Geometries That Were Once Impossible

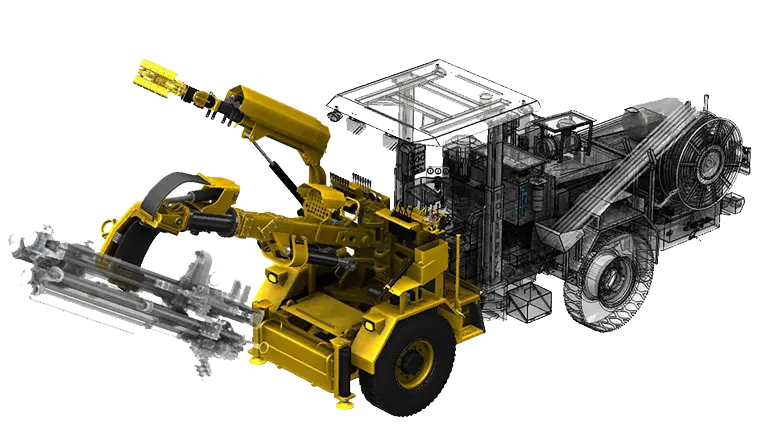

Probably the most significant of these ways in which investment casting services are adapting today is through the geometries that have been rendered possible. The geometries can now be cast with even intricate internal channels, a minimum of material waste, and highly optimized structures. This is a trend very visible in aerospace, where investment casting services are increasingly utilized to make turbine blades featuring not only thin wall sections but also complex internal cooling channels.

Besides, investment casting services can also be used to make both hollow and multi-material parts today, joining several metals into one casting. It allows manufacturers to fab parts with optimized properties, such as higher strength in some areas and better heat resistance in others, without resorting to unnecessary assembly procedures that may be very expensive and time-consuming.

Material Innovation in Investment Casting

The trend for lighter, stronger, longer-lasting materials has been rapidly accelerating in all minutes of the manufacturing sectors. To that end, investment casting services have responded by offering a broader range of materials and alloy combinations than ever before. The industries of aerospace, automotive, and energy drive forward the needs for more specialized and higher-performance materials, to which the inherent abilities within investment casting have made it increasingly valuable.

1. New Alloys and Metal Combinations

The reasons for the growth in investment casting services are not only design-related developments but also innovatory changes in materials. Conventionally, this kind of casting has been associated with metals like stainless steel, bronze, and aluminum. However, these days, with modern demands, companies offer a much wider range of high-performance materials, including titanium alloys, superalloys, and even precious metals such as gold and platinum.

The demand, for instance, has been increasingly rising in the aerospace industry for lighter and at the same time strong materials; hence, a greater usage of titanium and its alloys can be seen being cast through investment casting services. These materials possess superior strength-to-weight ratios, very good resistance to corrosion, and resistance to high temperatures. They are very important in turbine blades, compressor parts, and airframe components.

Moreover, the trend is toward investing in the art of using composite materials by most investment casting service providers that offer better mechanical properties than those of either metals or nonmetals, increased resistance to temperature, and many other features that provide a much longer lifespan.

2. Alloy Optimization for Sustainability

In addition to technology, the driving forces toward material innovation include sustainability. Many industries are under increasing pressure with regard to minimizing their impact on the natural environment. This translates to the optimization of materials even within the production process. Investment casting services contribute to sustainability in firms through their alloy optimization and recycling activities.

One important sustainability benefit of investment casting is reutilizing metal powders and scrap material. During the casting process, the waste generated can be recycled by manufacturers for the production of new parts that are going to reduce material costs and minimize the generation of waste.

In addition to such development, there is a growth of alloys in the direction of producing materials needing less energy during production and being recyclable more readily at the end of their product lives. The potential for casting the more sustainable class of alloys for intricate parts is the role contributing to the satisfaction of new environmentally related regulations or meeting corporate social responsibilities.

Improving Production Efficiency and Scalability

Among the key benefits of investment casting service is that for minimal material waste, parts result with very authentic accuracy. However, rising demands for shortening the turnaround time of their prototypes and increases in volume will surely drive each manufacturer to render more efficient and scalable processes of production. The industry has thus incorporated several strategies aimed at improving throughput for reducing lead time and generally to enhance efficiency altogether.

1. Automation and Robotics in Investment Casting

Mechanization of selected operations greatly improved productivity and consistency in the investment casting process. Robotics continue to enter mold preparation, shell building, and postcasting finishing. Where automation replaces work formerly done by a human operator, the number of defects can be reduced with the same effect on quality control, while the production time cycle is correspondingly shortened.

Besides, investment casting services can reduce labor costs by making use of automated systems, ensuring a higher degree of precision and repeatability in the final product. Automation also means smooth workflow, which ultimately allows companies to scale up operations and meet high demands for production, something very essential in industries such as automotive and defense.

2. Hybrid Manufacturing Techniques

Hybrid manufacturing-a combination of both investment casting services with other progressive technologies of additive manufacturing and traditional machining-continues to gain momentum. The hybrid approach really allows manufacturers to take advantage of multiple process benefits that improve production speed, cost efficiency, and product quality.

For example, 3D printing can be used to produce complex geometries for the core or mold to further develop in investment casting. In this way, not only is prototyping and part development considerably accelerated, but highly complex components can also be realized that would not have been achievable by traditional casting alone.

Hybrid techniques also allow for faster iteration of designs critical in industries where the cycle of product development is short, as in the case of the aerospace and automotive industries. These hybrid methods are changing how investment casting services can answer the demands imposed on modern manufacturing.

3. Digitalization and Lead Time Improvement

Due to the increasing demand for shorter lead times across industries, investment casting services are taking advantage of digital tools to help speed up the production process. Digital inspection tools, virtual simulations, and automated workflows have helped companies improve production timelines and reduce quality assurance time. Digital platforms allow for much better communication among the different parts of the supply chain.

With digitalization, the integrated platforms enable manufacturers to coordinative work amongst design teams, material suppliers, and foundries for casting-that the transition from design to production proceeds smoothly. Such integration is vital in an automotive context especially, where quick turnaround on parts keeps manufacturers competitive.

Investment Casting regarding Lightweighting

Now, with the demand for lightweight materials having the same value of strength in manufactured components, many different production units are looking ahead. Much attention has come up from sectors like aerospace and automotive to biomedical applications. All such goals could be effectively acquired by the method of investment casting services since it has unique design suitability for providing a highly stable output and reduced material part in manufacturing.

All in all, investment casting services include workpiece lightweight and a possibility for manufacturers to offer strong enough pieces while enabling extreme conditions because the advance in alloys allows innovative design techniques. In general, lightweight turbine blades made from some high-performance superalloys by investment casting contribute a lot in many space aircraft because those lightweight turbulences save much fuel by causing an increase in performance.

Lightweighting in Aerospace and Automotive Industries

With the increased need to produce fuel-efficient vehicles and aircraft, lightweight parts are in high demand across industries such as aerospace and automotive. Investment casting services are in a better place to take advantage of the demand since they can easily make parts that have intricate designs with thin-walled sections to minimize weight.

Investment casting services in the automotive sector are used in the making of lightweight suspension parts, engine components, and structural elements that enable car makers to meet fuel economy standards without sacrificing strength and durability.

Conclusion

The services of investment casting proved to be one of the most flexible and reliable processes of manufacture, acquiring modifications as dictated by the growing demands of all modern industries. Advances in design flexibility, material innovation, and production efficiency have positioned investment casting to better meet the challenges of the 21st century than at any time in the past. Investment casting services continue to be on the cutting edge in meeting the demands of modern manufacturing, whether by providing lightweight parts needed in the aircraft industry or optimizing materials for sustainability and improving production speed through automation." Investments cast have adapted very quickly to keep up with modern processes.

As industries constantly move towards pushing the barriers of potential manufacturing, investment casting techniques will always remain the fulcrum of innovation. From producing complex geometries, concocting high-performance alloys, or improving efficiency with hybrid techniques, this process is evolving to meet the demands of a fast-changing marketplace.

In assessing the interrelated state of investment casting services, material science, and industry trends, manufacturers will be able to unlock the complete potential of this age-old casting method, keeping it relevant in the twenty-first-century advance of modern manufacturing techniques.